Production System

We promise to provide safe, high-quality products

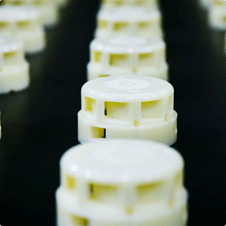

injection molding

![]()

We have an integrated production system from material procurement to injection molding of all plastic parts that make up the internal mechanisms of water meters. 24-hour operation at our plant allows us to design parts using CAD based on flow and structural analysis according to the properties of the resin, and we are able to produce parts that are used in the production of water meters. Utilizing the production technology for water meter parts, which require high-precision, microscopic processing, we will expand the manufacture of plastic parts in a wide range of fields beyond our own domain.

casting

![]()

The only water meter manufacturer with its own casting plant, Kashikei has established a lead-free and cadmium-free production system in consideration of the environment. The company's metal grain refinement technology improves the strength and casting efficiency of copper alloy castings and uses highly corrosion-resistant eco-tin for water supply. 8-year old water meters are collected and both metal and plastic parts are recycled and reused, thereby reducing the burden on the global environment.

cut

![]()

We have developed our original NC cutting machine exclusively for water meter manufacturing in collaboration with the manufacturer. Our factory technicians hone their skills by attending regular technical training sessions both in-house and outside the company, and by making full use of our CNC 4-station 18-axis indexing line, which is unique in the world, we are able to produce high-precision water meters.